The Importance of Automation in Car Manufacturing

Car manufacturing robots provide considerable advantages to the automotive industries. It merely improves the quality and shortens the warranty cost. Aside from this, it increases the production output and protects the individual against the hazardous threat in their respective workplace. To learn more about the benefits of automation, visit IntelLiDrives to learn more.

Nowadays, car manufacturing industries use robots specifically for welding and painting jobs. However, there are many other options to use robots throughout the entire automation system.

Most manufacturing companies prefer automation procedures in their operation. In the field of automotive, there are three characteristics of why they choose automation over human production: safety, capacity, and quality.

Safety

Jobs in the field of automotive are hazardous. So, in this case, automation will be considered as an alternative to mass production.

One great example is when pouring molten metals in the factory, or irritation of eyes due to exposure of arc welding. This type of operation is hazardous to each worker. However, automotive robots can resist all of these risks. It merely removes the possibility of an accident that will occur in the future. Also, it will prevent any injury claims by getting rid of the worker from this unsafe workplace and environment.

Capacity

Automotive manufacturing companies need to sustain work production to meet the demand of their clients. This operation procedure can be achieved easily through automation. Robots don’t have emotions. They can work continuously and produce constant working cycles throughout the day. Giving you a consistent peak production rate. Besides, you can program to run the robots even in breaks and holidays. This procedure will surely yield additional output and profit to your company compared to manual production.

Quality

Car factory robots are usually equipped with a good vision system. They can easily track any significant variations for incoming materials in car production. This course of action will inevitably translate to customer satisfaction, minimal mistakes, and meager warranty costs.

Significance of Automation in Automotive Manufacturing

There are a wide variety of automotive parts available in the market today. Most of the pieces require advanced robotics technology. It includes force sensing and vision systems that are compatible with the robotic application.

Below is some list of the best application of automation in car industries:

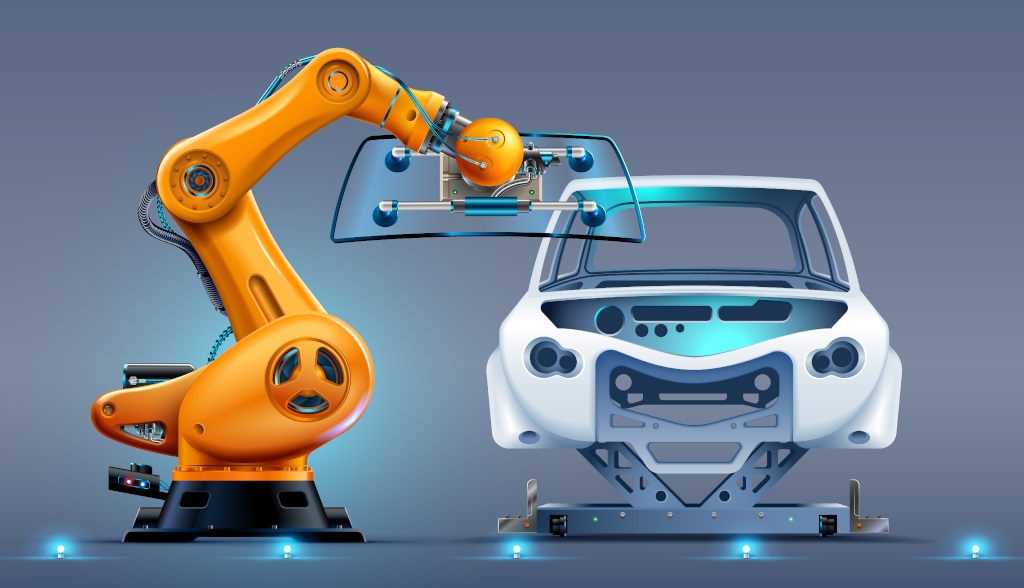

Car assembly

Tasks such as windshield installation, screw driving, wheel mounting, and calibration are all suitable for automation in car manufacturing plants.

Welding

Automated robots are highly recommended in welding jobs in car production compared to humans for various reasons. Robots have very high working standards. It always produces a consistent welding approach, especially when joining the car’s body. Giant robots with more exceptional capabilities can weld car body panels.

On the other hand, smaller robots can weld smaller parts like brackets and accessories. Robotics arc welding places the torch in a widespread orientation on each cycle. Then, with a repetitive level of speed and proper arc gap, it will inevitably produce superb quality output.

Machine Tending

Most car manufacturing companies utilize machine tending. It is a process that uses robotic automation to transport, interact, and remove the products in the system. A good example of machine tending is loading and unloading of hot molding from the die-casting machine.

- Transfer of Parts

Transferring metal stamps from one place going to the other or pouring hot molten metals going to the factory are impossible tasks for humans. Therefore, it is ideal to use the ability of robotic automation because it merely deals with such impossible functions that humans cannot handle.

- Removal of Material From the System

Robots are perfect assets if you want to reduce the total time of production. It is because it can follow a series of complex programs always. An example of this work includes cutting of fabrics, polishing the molds, and removal of flash from die casting or plastic molding.

Painting of Car Parts

Car automation follows a well-programmed path steadily. It is why most of the car manufacturing companies widely used robots, especially in car painting applications. It can easily handle different kinds of painting jobs, such as primers, sealants, and adhesives. Car painting using a robot application provides a tremendous advantage because it merely removes the hazardous effect of it on human health.

Robots are designed to bring comfort, more production output, and, most importantly, profit to any car manufacturing industries. Nowadays, with the continuing development of technology, robots are now easier to program and deploy in any workplace. That’s why most of the automotive manufacturers are interested in implementing robots in their operation. However, they should work with an experienced programming specialist to integrate sound design and applications to robot automation.